In 1972 the final Quartz Date watches from the single run

of 1000 were sold and Rolex abandoned the Beta 21 and began with a clean

slate designing their own quartz movement and a totally new watch to

house it. Over five years of research, design, and development went

into the 5035/5055 movement that would eventually power the Oysterquartz. The

end result is arguably the finest quartz movement that has ever been

made.

In moving away from the First Generation quartz

technology that characterized the Beta 21 and other early quartz

movements, Rolex recognized that two key elements to superior

accuracy in quartz timekeeping would be needed in their new quartz

movement: A higher frequency oscillator and some means to negate

the effects of temperature change on the stability of the oscillator.

Consequently, the oscillator used in the 5035/5055 was four times as fast as that used

in the Beta 21 and the module was one of the first quartz movements

to utilize analog thermocompensation. Oscillator stability over a

wide temperature range was accomplished through the use of a thermistor

to sense ambient temperature. Data from this sensor is sent to the electronic

control module which then regulates the voltage to the quartz crystal,

adjusting its rate accordingly. In addition, a rate trimmer is employed on the circuit

board which enables the

movement to be manually "fine tuned" during Rolex's

notoriously rigid internal testing and adjustment, something every Rolex

movement goes through before being sent to the COSC for

"official" chronometer certification. The rate trimmer

also allows for manual adjustment when the movement is serviced to compensate for the frequency drift that comes with the aging of the quartz crystal.

Approximately eighteen months after

the Oysterquartz was introduced the quartz crystal used in the oscillator

circuit was changed to a tuning fork shape. The earlier movements were

known internally at Rolex as Mark I movements, while the later ones with

the new shape quartz crystal were known as Mark II movements. The

Mark I 5035 Datejust movements were never submitted to the COSC for

chronometer certification, which accounts for the absence of

"Superlative Chronometer Officially Certified" on the dials of

the very early Oysterquartz Datejust models.

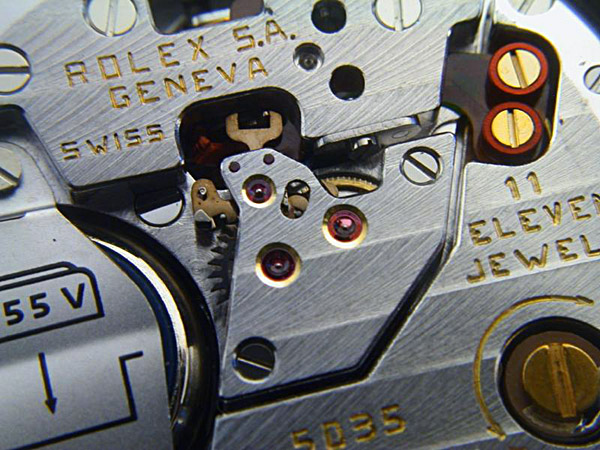

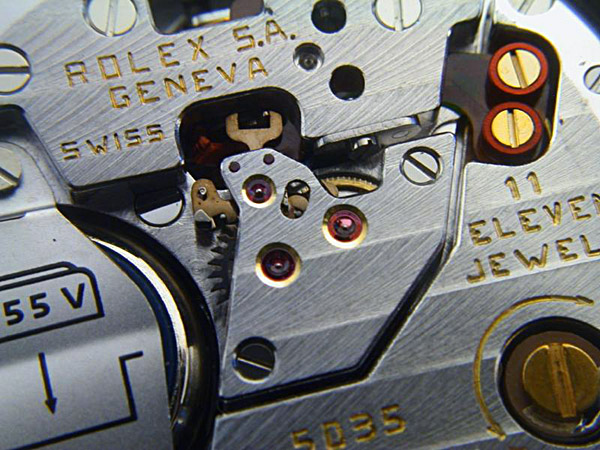

Everything about the design and construction of the

5035/5055 module shows that Rolex intended this movement to be a "lifetime" movement, designed to be serviceable and serviced just like their mechanical movements. In fact, apart from the electronics and the pulse motor, the "mechanics" of the 5035 are the same as the 3035 automatic movement that was

also introduced in 1977 and used in the Submariner and other Date/Datejust models for over a decade.

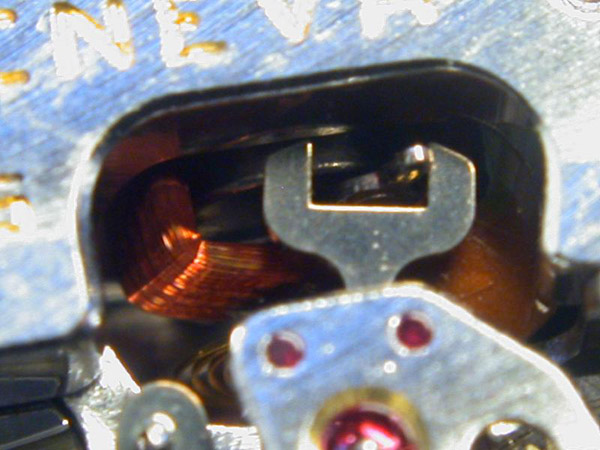

The drive mechanism for the 5035/5055 is

very similar to the design of a traditional mechanical watch escapement.

The pulse motor drives a pallet fork which in turn moves a pallet wheel.

This wheel drives the second hand at a 1:1 ratio with one tick per

second. The hour and minute hands are driven off this pallet

wheel. The loud "tick" you hear every second are the pallets

engaging the pallet wheel. That is why the tick of the 5035/5055 has

such a unique sound and is very much like the tick of a mechanical watch,

though at one tick per second rather than the eight ticks per second of a

28,800 bph Rolex Perpetual movement. This drive mechanism also ensures the

second hand steps around the dial smartly with zero backlash since the

hand is effectively locked in place by the pallet fork in between each

beat.

Even though the technology of quartz

wristwatch timekeeping has moved beyond that found in the 5035/5055,

this movement still remains one of the most "over-engineered" quartz movements ever

produced and clearly carries on the Rolex tradition of solid

engineering, superb finishing, and understated beauty. Advancements in

technology have yielded quartz modules with superior accuracy, but when

it debuted, the

5035/5055 only had one true rival from a technological standpoint: the

2.4Mhz Omega 1516 movement used in their famous Marine Chronometer

wristwatches of the mid 70s. But from the standpoint of "build

quality" and finish (anglage, perlage, and Geneva stripes), the 5035/5055 still reigns supreme, something

that is not likely to change in the foreseeable future.

|

5035 Specifications:

32,768Hz VCTCXO Quartz Module

Integrated

circuit: CMOS

Temperature

compensation: Yes

Rate

trimmer: Yes

Power source:

UCAR 357 silveroxide battery, 1.55v

Width: 29.75mm

Height: 6.5mm

11 jewels

Antimagnetic: Yes, to 1000 Oersted

Hacking: Yes

Quick set date: Yes

|

5055 Specifications:

32,768Hz VCTCXO Quartz Module

Integrated

circuit: CMOS

Temperature

compensation: Yes

Rate

trimmer: Yes

Power source: UCAR 357 silveroxide battery, 1.55v

Width: 29.75mm

Height: 7.1mm

11 jewels

Antimagnetic: Yes, to 1000 Oersted

Hacking: Yes

Quick set day-date: Yes

|

|